Priming in Centrifugal Pumps: What You Need to Know

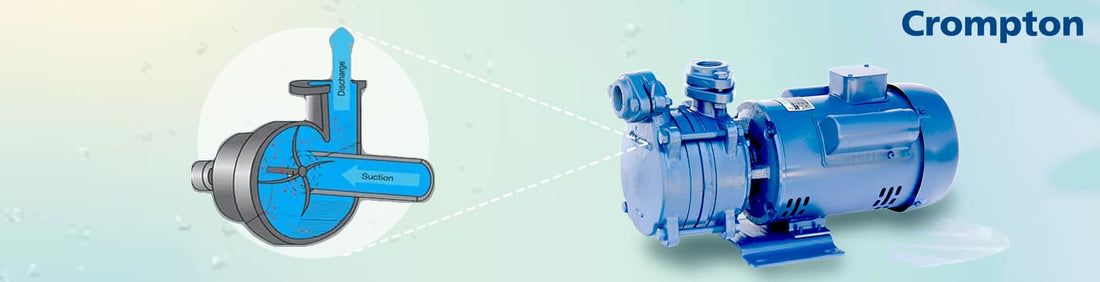

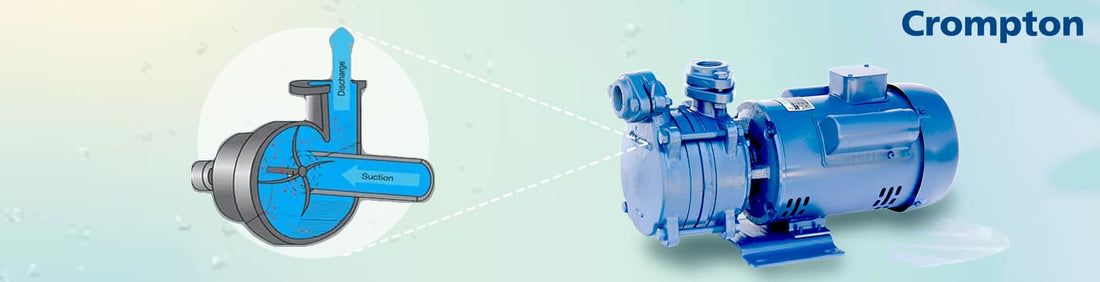

Priming is a crucial process in centrifugal pumps that ensures the pump is filled with fluid before it is started. The priming process involves filling the pump casing with the fluid to be pumped, removing any air from the casing, and creating a seal between the impeller and the casing. This can be done manually or automatically, depending on the type of pump.

Understanding how Priming works in Pumps

Wondering what is priming in a centrifugal pump? Read this section to understand the procedure in a better manner.

Priming in centrifugal pumps utilises a priming chamber, which is a separate section of the pump that allows for the removal of air and the creation of a vacuum. The priming chamber is designed to facilitate the priming process by providing a space where the fluid can be drawn in and any air can be expelled.

Another interesting aspect of priming is the impact it can have on pump performance. A poorly primed pump can result in reduced efficiency, increased energy consumption, and even damage to the pump itself. On the other hand, a properly primed pump can operate more efficiently, with lower energy consumption and longer lifespan.

Why is Priming Necessary?

Priming in centrifugal pumps is essential because of the below-mentioned reasons.

- Without priming, there may be air trapped inside the pump casing, which can prevent the pump from generating the necessary pressure to move the fluid through the system

- A dry pump can overheat and cause damage to the impeller, seal, and bearings

- Priming ensures that the pump is filled with the fluid to be pumped, which is necessary for proper lubrication and cooling of the pump’s internal components

- A well-primed pump operates more efficiently, with lower energy consumption and less wear and tear on the pump’s components

- In certain applications, such as firefighting or irrigation, it may be necessary to prime the pump quickly in order to prevent damage or loss of life

- Priming can also help to prevent cavitation, which occurs when the pressure inside the pump drops too low and bubbles form in the fluid. Cavitation can cause damage to the impeller and reduce the pump’s efficiency

How do you Prime a Centrifugal Pump?

Want to understand how priming in pumps is carried out? Follow the below-mentioned steps to efficiently pump water to prevent wear and tear.

- Ensure that the pump is properly installed and that all valves and connections are secure

- Open the suction valve and ensure that the suction line is free of any obstructions

- Fill the pump casing with the fluid to be pumped until it is level with the suction port

- Close the vent valve on the top of the pump casing

- Close the discharge valve

- Turn on the pump motor and allow it to run for a few seconds to create a vacuum in the pump casing

- Open the vent valve to release any air trapped inside the pump casing. Air will be replaced by the fluid being pumped

- Close the vent valve once the fluid has displaced all of the air in the pump casing

- Open the discharge valve and adjust the flow rate as necessary

- Monitor the pump to ensure that it is operating correctly and without any issues

When is Priming not required?

In some instances, priming in pumps is not needed. These include

- Self-priming pumps: Some types of pumps, such as self-priming pumps, do not require priming because they have a built-in mechanism that allows them to evacuate any air in the system automatically. These pumps are designed with a reservoir that contains enough fluid to create a vacuum, which can then be used to draw fluid into the pump

- Submerged pumps: Pumps that are completely submerged in the fluid being pumped may not require priming because they are always filled with the fluid. In these cases, the pump may need to be primed initially to ensure that there is no air trapped in the system, but once it is filled with fluid, it should not require priming again

- Gravity-fed systems: In some applications, the fluid being pumped may be supplied by gravity, which means that no priming is necessary. For example, in a hydroelectric power plant, water flows down from a reservoir to turn a turbine, and a pump may be used to return the water back to the reservoir. In this case, the pump may not need to be primed because the water is already under pressure due to the force of gravity

What is a Self-Priming Pump?

A self-priming pump is a type of pump that is designed to evacuate air from the suction line and pump casing automatically, without the need for manual priming. This makes them useful in situations where the fluid being pumped may contain air or gas, or where the pump may be located above the fluid source.

How does a Self-Priming Pump work?

Self-priming pumps are typically used in applications where the pump may be located above the fluid source or where the suction line may be prone to air pockets or other obstructions. Their working includes

- The pump is turned on, and the impeller begins to rotate, creating a low-pressure area inside the pump

- Air is drawn into the pump through the suction line, mixing with the small amount of fluid in the priming chamber

- The impeller continues to rotate, creating a centrifugal force that pushes the air and fluid mixture towards the discharge outlet

- As the mixture reaches the discharge outlet, it passes through the check valve, which closes and prevents the fluid from flowing back into the priming chamber

- The air in the mixture is then separated from the fluid as it enters the pump volute, creating a vacuum inside the pump

- The vacuum draws more fluid into the pump chamber through the suction line, and the cycle continues until the pump is fully primed

- Once the pump is primed, it operates like a standard centrifugal pump, moving fluid through the system and generating the necessary pressure to meet the required flow rate

Are there any Precautions to using Self-Priming Pumps?

While using self-priming pumps, you need to be aware of the following factors.

- Prevent dry running: One of the main precautions with self-priming pumps is to avoid running the pump dry. Self-priming pumps rely on a certain amount of fluid in the pump chamber to create a vacuum and prime the pump. If the pump runs dry, the impeller can heat up and warp, causing damage to the pump. Always ensure that the pump is properly primed before starting it up

- Monitor for leaks: Another precaution is to monitor the pump for any leaks in the suction line or discharge line. Air leaks can disrupt the priming process and prevent the pump from operating properly. Fluid leaks can also cause damage to the pump motor and other components

- Regular maintenance: Finally, it’s important to perform regular maintenance on self-priming pumps to ensure that they continue to operate effectively. This includes checking the impeller and seal for wear, inspecting the suction line and discharge line for leaks, and checking the priming chamber for proper fluid levels. Regular maintenance can help to prevent costly repairs and prolong the life of the pump

Read Previous Blog

Read Previous Blog

at 9228880505 or write to us at

at 9228880505 or write to us at